Ocean Newsletter

No.594 June 20, 2025

-

Background of the "BLUE OCEAN DOME" Exhibit with the Theme of "Resuscitating the Ocean"

TAKEUCHI Mitsuo (Director, ZERI JAPAN (Certified NPO))

Following the 2019 G20 "Osaka Blue Ocean Vision" declaration, ZERI JAPAN decided to participate in the Osaka-Kansai Expo. "BLUE OCEAN DOME," which is exhibiting at the Expo, is the only private pavilion with an ocean theme. Under the banner of "Resuscitating the Ocean," it is aiming through a variety of exhibits to prevent plastic marine pollution, utilize the ocean sustainably, and promote understanding of ocean climate change.

-

Hannan City's Initiatives Toward the Osaka-Kansai Expo, with Satoyama and Satoumi as their Fields of Focus

MAEDA Masahiro (Vice Director of the Future Creation Department, Hannan City, Osaka Prefecture, and Head of the City Vitality Creation Division)

Hannan City is working on 51 projects to achieve the SDGs in preparation for the Osaka-Kansai Expo, centering on blue carbon, and with the aim of restoring ecosystems and realizing a sustainable society. We aim to encourage the next generation of children to take an interest in environmental conservation through marine education, to promote the blue economy, and achieve economic growth. Through public-private collaboration, we aim to increase learning and experiences of environmentally friendly living, and to create a sustainable future for the region.

-

Development and Social Implementation of Hydrogen Fuel Cell Ships

ODE Tsuyoshi (Specially Appointed Professor, Ph.D., Tokyo University of Marine Science and Technology)

In order to realize a carbon-neutral society, the maritime sector is also being called upon to accelerate the social implementation of zero-emission ships. The pure hydrogen fuel cell ship "Mahoroba" and its energy supply system, which began commercial operation at the Osaka-Kansai Expo in April 2025, represent the first social implementation in Japan. Although hydrogen fuel cell ships have issues with size and cruising range, they are suitable for use as urban transportation modes operating over short distances, such as water buses, and we hope that efforts will be made to popularize them in areas such as certification and inspection of products and equipment.

Development and Social Implementation of Hydrogen Fuel Cell Ships

KEYWORDS

Zero Emission Ships / Carbon Neutral / Pure Hydrogen Fuel Cell-Powered Passenger Ship “Mahoroba”

ODE Tsuyoshi (Specially Appointed Professor, Ph.D., Tokyo University of Marine Science and Technology)

In order to realize a carbon-neutral society, the maritime sector is also being called upon to accelerate the social implementation of zero-emission ships. The pure hydrogen fuel cell ship "Mahoroba" and its energy supply system, which began commercial operation at the Osaka-Kansai Expo in April 2025, represent the first social implementation in Japan. Although hydrogen fuel cell ships have issues with size and cruising range, they are suitable for use as urban transportation modes operating over short distances, such as water buses, and we hope that efforts will be made to popularize them in areas such as certification and inspection of products and equipment.

Carbon Neutrality in Shipping

For realizing carbon neutrality in the maritime industry, the widespread adoption of zero-emission ships powered by ammonia, hydrogen, and other alternatives to fossil fuels is crucial. The Ministry of Land, Infrastructure, Transport and Tourism's (MLIT) roadmap to realize this goal envisions hydrogen for short to medium-range marine engines and ammonia for long-range engines. For hydrogen utilization, there are hydrogen fuel cell ships for small, short-distance applications and hydrogen gas-fueled ships for large, long-distance vessels, which are diesel substitutes. Acceleration of the social implementation of these technologies is crucial to achieve carbon neutrality by 2050. As an initiative for hydrogen fuel cell ships, the pure hydrogen fuel cell ship “Mahoroba” and its energy supply system, which began commercial operation at the Expo 2025 Osaka, Kansai Japan in April 2025, represent Japan's first social implementation.

Toward Social Implementation of Hydrogen Fuel Cell Ships

Tokyo University of Marine Science and Technology has been advancing research and development by installing fuel cells on the full-battery experimental vessel “Raicho N” since 2016. In 2019, Iwatani Corporation and Tokyo University of Marine Science and Technology began planning the construction of hydrogen fuel cell ships. In 2021, the New Energy and Industrial Technology Development Organization (NEDO) conducted demonstration operations of a hydrogen fuel cell ship under the theme “Development and Demonstration of Hydrogen Fuel Cell Ships and Energy Supply Systems Enabling Commercial Operation,” which was selected as a project under the “Collaborative Industry-Academia-Government R&D Project for Solving Common Challenges Toward Dramatically Expanded Use of Fuel Cells and Related Technologies/Technology Development for Multi-Purpose Application of Fuel Cells.” The project aims to achieve commercially viable, economically feasible solutions. The implementing organizations are Iwatani Corporation, Kansai Electric Power Co., Inc., Namura Shipbuilding Co., Ltd., and Tokyo University of Marine Science and Technology.

Safety Guidelines and Ship Inspection

To safely handle hydrogen fuel and prevent fires and explosions, the “Safety Guidelines for Hydrogen Fuel Cell Ships” (MLIT) have been established. These guidelines apply to ships used under the following conditions for hydrogen fuel cell ships: (1) power source is a combination of fuel cells and storage batteries, (2) use of polymer electrolyte fuel cells, (3) hydrogen supply to ships via mobile hydrogen stations or portable hydrogen cylinders (liquefied hydrogen not applicable), (4) fuel tank design pressure of 70 MPa or less, (5) hydrogen used as compressed gas with oxygen taken from the air. The guidelines establish technical standards necessary for safe design, construction, and operation of hydrogen fuel cell ships.

Only three ships have satisfied these regulations and obtained ship inspection certificates, with only two pure hydrogen fuel cell ships: Tokyo University of Marine Science and Technology's experimental ship “Raicho N” and Iwatani Corporation's passenger ship “Mahoroba,” which will operate at the Expo 2025. “Raicho N” was the first in Japan to receive a ship inspection certificate as a hybrid-controlled, pure fuel cell ship capable of operating solely on hydrogen fuel cells and lithium-ion secondary batteries, demonstrating for the first time in Japan the feasibility of building and operating pure hydrogen fuel cell ships. These results are reflected in the construction and operation of “Mahoroba.”

Only three ships have satisfied these regulations and obtained ship inspection certificates, with only two pure hydrogen fuel cell ships: Tokyo University of Marine Science and Technology's experimental ship “Raicho N” and Iwatani Corporation's passenger ship “Mahoroba,” which will operate at the Expo 2025. “Raicho N” was the first in Japan to receive a ship inspection certificate as a hybrid-controlled, pure fuel cell ship capable of operating solely on hydrogen fuel cells and lithium-ion secondary batteries, demonstrating for the first time in Japan the feasibility of building and operating pure hydrogen fuel cell ships. These results are reflected in the construction and operation of “Mahoroba.”

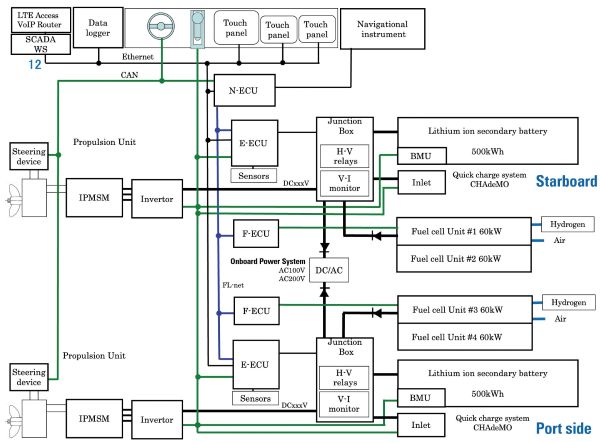

Pure Hydrogen Fuel Cell Passenger Ship “Mahoroba”

“Mahoroba,” which began commercial operation at the Expo 2025 Osaka, Kansai, Japan, is a catamaran with a gross tonnage of 177 tons and a 150-passenger capacity, powered by a combination of hydrogen fuel cells and lithium-ion secondary batteries. The maximum cruising range is approximately 150 km, obtaining a total of about 3,100 kWh of energy from hydrogen and lithium-ion batteries for navigation.

This is equivalent to the hydrogen capacity of 28 Toyota Mirai fuel cell vehicles and the lithium-ion secondary battery capacity of 25 Nissan LEAF EVs. However, from the perspective of the “Life Cycle Assessment (LCA),” which evaluates environmental impacts including the processes of producing hydrogen and electricity as fuels, zero emission cannot be achieved unless environmental burden is reduced not only from Tank (fuel tank) to Wake (wake-wave) but also from Well (well) to Tank (fuel tank), that is from the manufacturing process.

“Mahoroba's” system is broadly divided into four parts. The electric propulsion system for moving the ship, the fuel cell power generation system for creating electrical energy, the navigation system for safe sailing, and the ship service system for operating onboard lighting, air conditioning and other systems. These systems work together to operate the ship efficiently and safely (see Figure 1 System Block Diagram).

This is equivalent to the hydrogen capacity of 28 Toyota Mirai fuel cell vehicles and the lithium-ion secondary battery capacity of 25 Nissan LEAF EVs. However, from the perspective of the “Life Cycle Assessment (LCA),” which evaluates environmental impacts including the processes of producing hydrogen and electricity as fuels, zero emission cannot be achieved unless environmental burden is reduced not only from Tank (fuel tank) to Wake (wake-wave) but also from Well (well) to Tank (fuel tank), that is from the manufacturing process.

“Mahoroba's” system is broadly divided into four parts. The electric propulsion system for moving the ship, the fuel cell power generation system for creating electrical energy, the navigation system for safe sailing, and the ship service system for operating onboard lighting, air conditioning and other systems. These systems work together to operate the ship efficiently and safely (see Figure 1 System Block Diagram).

■Figure 1: External View and System Block Diagram of Hydrogen Fuel Cell Passenger Ship “Mahoroba”

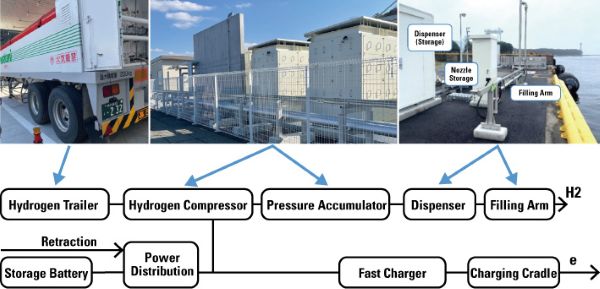

Hydrogen Fuel Bunkering

Supplying fuel to a vessel is called bunkering, whether it is charging the vessel’s lithium-ion secondary batteries or filling the vessel’s tanks with hydrogen. Hydrogen bunkering is the biggest challenge for the widespread adoption of hydrogen fuel cell ships. Currently, there are no specific regulations for directly filling hydrogen into ships, but specialized measures beyond those used at standard hydrogen stations will be necessary. On the technical side, considerations must include salt damage from seawater, corrosion, rust, and equipment loads due to ship motion, and an emergency breakaway coupler must also be installed. Currently, Kansai Electric Power Co. has completed a bunkering facility at their Nanko Power Station in Osaka. This facility can handle both hydrogen and battery charging simultaneously.

■Figure 2: Bunkering System

Toward Widespread Adoption of Hydrogen Fuel Cell Ships

Hydrogen fuel cell ships have several advantages such as reduced vibration, noise, and the absence of oil smells, along with a lower environmental impact, but face challenges in scaling up and cruising range due to the low energy density of the fuel used. Ships are built and operated with diverse vessel types and propulsion systems tailored to their specific purpose. Hydrogen fuel cell ships are considered suitable for widespread use in short distance urban transportation systems, like water buses. To this end, efforts to certify products and new technologies already in use on land as ship equipment are critical; these include hydrogen fuel cell units, hydrogen fuel tanks, battery systems, and power converters. Furthermore, hydrogen fuel cell ships use products and components that require no maintenance for certain periods, such as electric motors, power converters, lithium-ion secondary batteries, and fuel cells, making them maintenance-free and operator-friendly. For hydrogen fuel cell ships, once methods for conforming to inspections according to the “Hydrogen Fuel Cell Ship Safety Guidelines” are in place, more shipyards will be able to build ships, and ship owners will be able to operate them safely. Additionally, since most of the equipment on these vessels is electrified, they enable not only maintenance-free operation but also easy monitoring through automatic measurement, facilitating conditions assessment and enabling shore-based support. If such advanced ship safety management systems can be built, it will enable land-based engineers to monitor and manage several ships, potentially contributing to alleviating the serious shortage of engineers on domestic vessels.