- Top

- Publications

- Ocean Newsletter

- Liquefied Hydrogen Carrier Paving the Way to a Decarbonized Society

Ocean Newsletter

No.505 August 20, 2021

-

Liquefied Hydrogen Carrier Paving the Way to a Decarbonized Society

NISHIMURA Motohiko

Executive Officer and Deputy General Manager, Hydrogen Strategy Division, Kawasaki Heavy Industries, Ltd.

Selected Papers No.27Momentum is rising in Japan and abroad towards hydrogen energy as a trump card for achieving a decarbonized society. In order to further society’s adoption of hydrogen energy, Kawasaki Heavy Industries is aiming to commercialize the international CO2-free hydrogen supply chain, for which it is now launching its pilot demonstration. The results of this demonstration, which involves the long-distance marine transport of liquefied hydrogen using the world’s first liquefied hydrogen carrier, will be the cornerstone of the future of decarbonized society and hydrogen provision.

Selected Papers No.27 -

Ecological Infrastructure that Supports a Sustainable Society

WASHITANI Izumi

Professor Emeritus, The University of TokyoResearchers aiming for the conservation and restoration of the natural environment have proposed the concept of “ecological infrastructure,” which contributes towards the conservation of biodiversity and is low-cost without limiting the choices of future generations. I would like to recommend applying “nature-based solutions” to Japan’s seashores as an approach which has gained importance abroad in measures for mitigating climate change as well as in disaster prevention. -

Practicing Organic Aquaculture at Noto’s Satoyama and Satoumi

MATSUBARA Hajime

Director, Noto Center for Fisheries Science and Technology, College of Science and Engineering, Kanazawa University“Organic” is a term used mostly for agriculture. Aquaculture is conducted on a fluid water surface, making it nearly impossible to be stably managed and difficult to establish a clear organic standard for its products. Chemical-free organic aquaculture is currently being developed; in this article, I would like to introduce organic aquaculture that is focused on the Tiger pufferfish.

Liquefied Hydrogen Carrier Paving the Way to a Decarbonized Society

Momentum is rising in Japan and abroad towards hydrogen energy as a trump card for achieving a decarbonized society. In order to further society’s adoption of hydrogen energy, Kawasaki Heavy Industries is aiming to commercialize the international CO2-free hydrogen supply chain, for which it is now launching its pilot demonstration. The results of this demonstration, which involves the long-distance marine transport of liquefied hydrogen using the world’s first liquefied hydrogen carrier, will be the cornerstone of the future of decarbonized society and hydrogen provision.

Moves Toward Decarbonization and Use of Hydrogen

In recent years, Japan and other countries worldwide have been experiencing frequent extreme weather events and disasters. These phenomena are believed to be caused by global warming. Therefore, reducing greenhouse gas, which are thought to cause global warming, have become a pressing societal issue for all mankind. The Paris Agreement, an international framework for combating global warming, came into effect in November 2016. As a result, France, the United Kingdom, and other countries have legislated net zero emissions by 2050. By comparison, Japan has set a greenhouse gas reduction target for FY2030 of 46% below FY2013 level, intending to become carbon neutral by 2050. Clearly, this goal cannot be achieved by energy conservation alone, and promoting the introduction of renewable energy (RE) is essential. However, since Japan is already one of the world's top countries for RE installation density (annual RE power generation divided by inhabitable area), there are issues surrounding locations for further installation and cost reduction. Additionally, Japan has one of the highest energy consumption densities in the world. Given these facts, there are significant constraints in supplying the large amounts of energy required by introduction of large-scale RE and its expansion in such a limited land area.

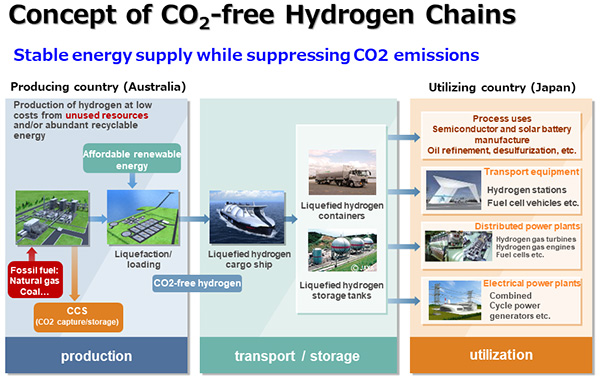

Against this background, there is a need for a new type of zero-emission energy. This energy must be able to be introduced at scale at low cost, helping realize a carbon-free society while satisfying the future energy selection criteria of Energy Security, Economic Efficiency, and Environment in a Safe manner (3E+S). This situation has brought attention to the concept of producing hydrogen overseas from inexpensive unused resources and RE for importation into Japan.

Development of a CO2-Free Hydrogen Supply Chain

Realizing a hydrogen society—where hydrogen is commonly used as energy in the same way as oil and natural gas—requires a stable hydrogen supply. However, it is difficult to produce large amounts of hydrogen stably and economically in Japan, where resources are scarce and land area is limited. Being an island nation, it is also impractical to import hydrogen through gas pipelines. Thus, one promising option is the importation of hydrogen produced overseas using marine transportation. Given these circumstances, in 2010 our company announced a CO2-free hydrogen supply chain concept in which hydrogen is produced by the gasification of lignite coal, an unused resource from the Latrobe Valley in Victoria, Australia, refined and liquefied. The liquefied hydrogen is transported to Japan by sea on a dedicated carrier (see figure).

This concept aims to realize the production and transportation of CO2-free hydrogen with sequestering CO2 produced during the hydrogen production process from the lignite coal into geological formations through CCS (CO2 capture and storage), thereby realizing a hydrogen and decarbonized society. To realize this concept, a pilot demonstration project (project) was launched in fiscal 2015 using a liquefied hydrogen carrier with a transport capacity of about 1/120 of the commercial scale. The carrier was built with support from the New Energy and Industrial Technology Development Organization (NEDO), a national research and development agency. To proceed with the demonstration, the CO2-free Hydrogen Energy Supply-chain Technology Research Association "HySTRA"* was formed in February 2016 with Iwatani Corporation, Shell Japan Ltd., and Electric Power Development Co., Ltd. (Marubeni Corporation, ENEOS Corporation, and Kawasaki Kisen Kaisha, Ltd. have since joined).

The project aims to establish and demonstrate technologies for gasification of lignite coal, as well as the long-distance mass marine transportation of liquefied hydrogen and its cargo handling system (loading/unloading) between cargo tanks on ships and tanks on land which require a high level of technological development. Among these technologies, the world's first liquefied hydrogen carrier will connect Australia and Japan as a form of long-distance mass marine transport. In December 2019, a naming and launching ceremony was held at our Kobe Works, with 4,000 people in attendance, for the vessel named "Suiso Frontier." This name is based on the hope that we will be able to pioneer a hydrogen society, set sail to new frontiers (new worlds and cutting-edge technologies), and make the Japanese word for hydrogen - suiso - known to people around the world.

The world's first liquefied hydrogen carrier “Suiso Frontier”

Liquefied hydrogen carrier “Suiso Frontier”

Liquefied hydrogen carrier “Suiso Frontier”

The International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (commonly known as the IGC Code), adopted by the International Maritime Organization (IMO), covers LPG and LNG, but not liquefied hydrogen. In response, the maritime authorities of Japan and Australia started discussions on safety requirements for the operation of bulk liquefied hydrogen carriers (such as the pilot ship) in 2014. In November 2016, the IMO adopted the interim recommendations for carriage of liquefied hydrogen in bulk jointly proposed by these two countries. At present, the ship designed and built applying this interim recommendation is the Suiso Frontier only. It is hoped the vessel will contribute to future revisions of international regulations through international operations of bulk liquefied hydrogen transportation.

The Suiso Frontier is 116.0 meters long, 19.0 meters wide (molded width), 10.6 meters deep (molded depth), has a carrying capacity of 25 people and is equipped with one cargo tank. The tank requires extremely high insulation performance to store the liquefied hydrogen at minus 253 degrees Celsius and a rational design that is sufficiently robust to withstand rough seas and yet easy to maintain. For this reason, the tank uses a vacuum-insulated double-shell structure and glass-fiber reinforced plastic for the components supporting the inner tank. These choices make it resistant to heat transfer and provide excellent strength. The tank has a capacity of 1,250 m3 and is capable of transporting 75 tons of liquefied hydrogen. When developing and designing the vessel, we utilized LNG carrier technologies and onshore liquefied hydrogen transportation and storage technologies that our group had built up over many years, thus demonstrating the synergy to be found among the Kawasaki Group.

Sea trial operations were completed in October 2020, and final equipment adjustments and preparations for delivery are currently underway. The vessel will be handed over to HySTRA, the primary implementer of the demonstration project. It will then be used to demonstrate handling liquefied hydrogen as cargo at the Kobe LH2 Terminal on Kobe Airport Island. In the second half of FY 2021, the vessel will be loaded with liquefied hydrogen and make a 9,000-km round-trip voyage between Kobe and the Port of Hastings in Australia.

Toward Full-Scale Commercialization

In addition to the pilot demonstration, we have also been working on developing large scale equipment for the supply chain. For example, in April 2021, our company developed a cargo containment system (CCS) offering the world's largest capacity (40,000 m3 class per tank), for installation on a large-scale liquefied hydrogen carrier and obtained the Approval in Principle (AiP) from Nippon Kaiji Kyokai (ClassNK). We are currently developing a 160,000m3 liquefied hydrogen carrier equipped with four of these CCS tanks, with the aim of starting demonstration operation in mid-2020s. Liquefied hydrogen carriers are essential for Japan, a nation surrounded by the ocean, to achieve both energy security and decarbonization. We hope to build a supply chain that can supply hydrogen from overseas at low cost and in a stable manner, while leading the world in working towards its practical application. (End)

- *CO2-free Hydrogen Energy Supply-chain Technology Research Association (HySTRA) http://www.hystra.or.jp/en/